Waterjet Cutting

It’s simply the most versatile cutting method used in manufacturing today. Bespoke parts, one-offs or batch production it’s more than capable. Known for it’s beautiful cut quality as standard.

Enquire about waterjet cutting

our services

materials

We’ve listed some typical materials here that we frequently profile for our customers but with the Waterjet being able to cut so much more it’s ridiculous to try and list them all – and it would be a pretty boring read!

If you have a material that you would like to use to profile but unsure of what method would be the best suited and can’t see it here then give us a call or use the contact page and we can give you a little guidance.

stainless steel

Ah… Our bread and butter. Our reputation at RPS has been built on this material. We cut stainless steel for use in many applications and industries, with no burn marks or cracking, and always have a massive range of stock on hand at all times.

mild steel

The go-to material for the fabrication and manufacturing industry. Cost effective, robust and can be manipulated to suit many products easily. We stock a huge range of this material and have the ability to cut large profiles with our 4000 x 2000mm machine.

wood

Hard woods like Oak and Beech are perfectly suited for profiling with a Waterjet system. Intricate patterns, curves and lines can be produced in the material whilst leaving a beautiful edge quality ideal for furniture manufacture and outdoor projects.

aluminium

A quick cutting material on our waterjet and used widely. Aluminium is lightweight, strong and resistant to corrosion. Up to 300mm thick can be profiled with zero heat affected zones or material stresses.

titanium

A very tough and hardy material but also very lightweight. Used widely in the aerospace, medical and architectural industries and known for its trademark shimmer & shine.

plastics

Plastics of all types can be profiled using the Waterjet method. With no heat affected zones or distortion caused by temperature transfer, the profile can be cut with minimal risk of de-lamination or scaring.

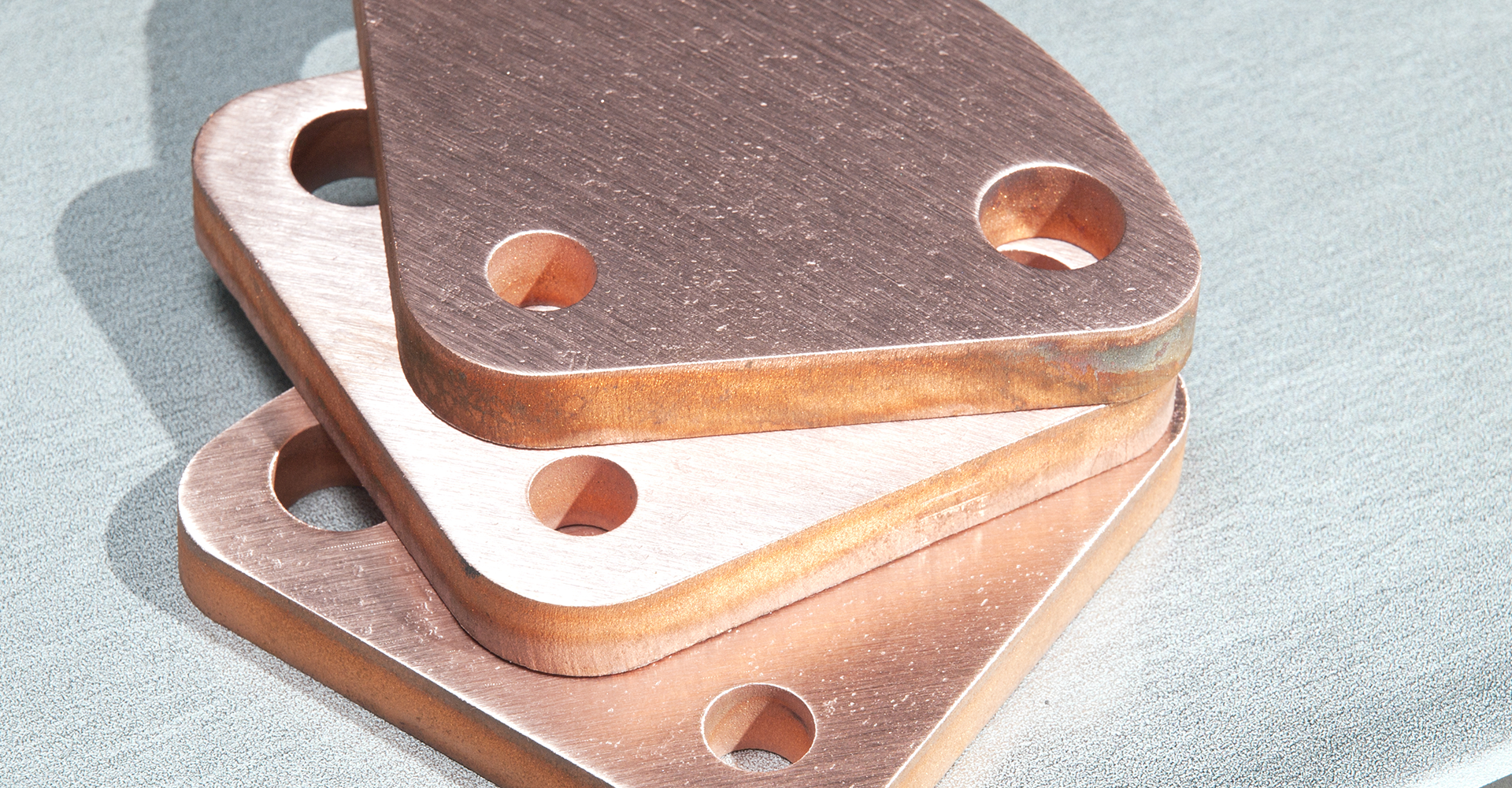

copper & brass

Copper has an excellent electrical and thermal conductivity, which makes it not so great for Plasma or Laser cutting but perfect for the waterjet.

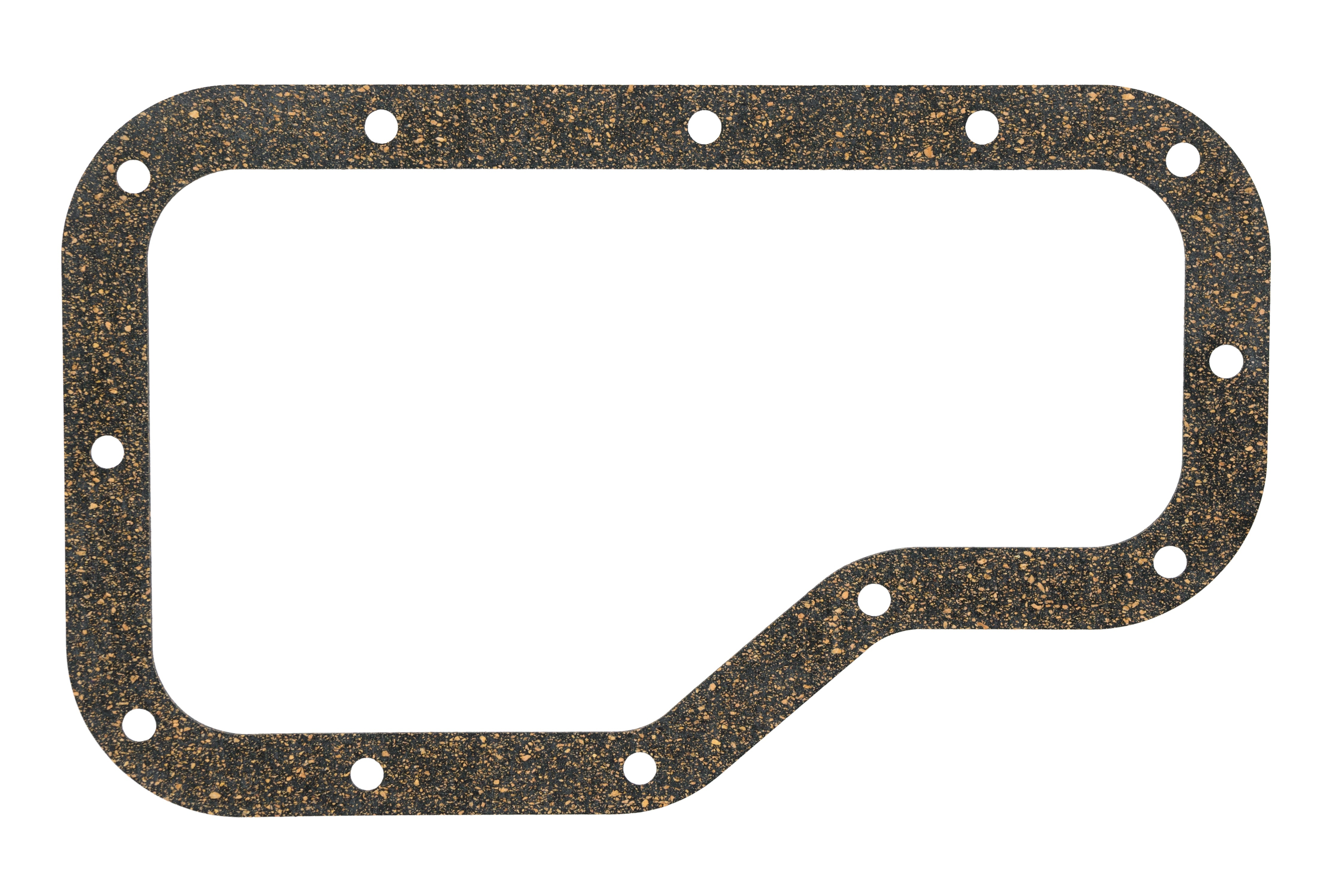

rubber, gasket & foam

Our Waterjet has the ability to use pure water to cut materials, which makes cutting rubber, gasket and foams to any profile quick and beautifully accurate.

carbon fibre & fibre glass

One major advantage of using a Waterjet is the ability to cut fibre reinforced materials, such as carbon fibre and fibre glass. The material doesn’t even need to be flat as the Waterjet will cut profiles even out of elevated work sufaces.

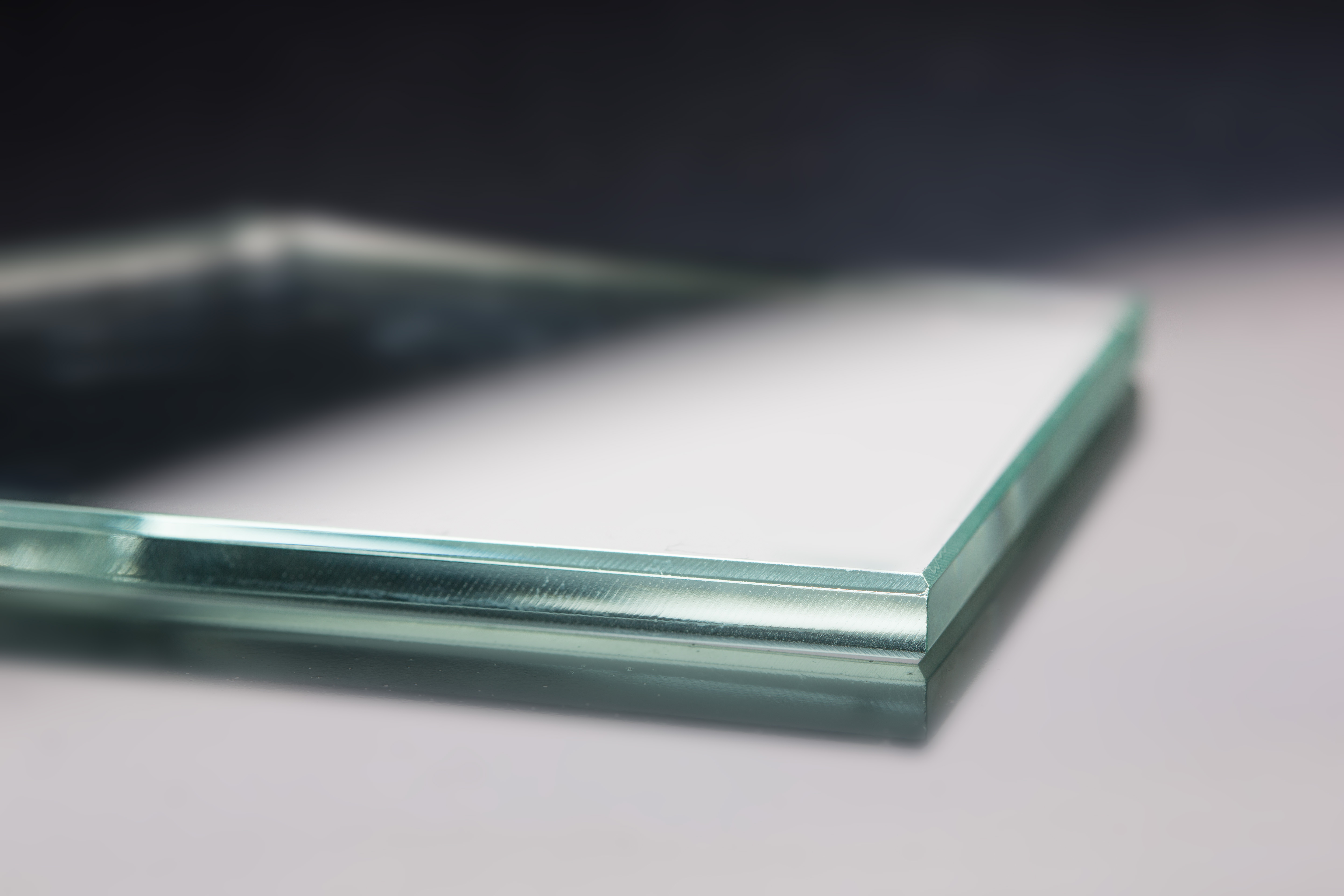

glass

Our waterjet has the ability to cut glass profiles, including curves, angles and intricate designs.

marble, granite and stone

Marble, Granite, Ceramics, Slate and Natural stone can all be Waterjet cut to accurate sizes and shapes – perfect for kitchen worktops and outdoor features.